Lab

The research facilities of the Center for Thermo-Mechanics and Failure of Materials (CTMFM) include a 300 KN MTS exceed system equipped with a build in furnace (up to 500C) which enables mechanical testing at high temperatures. In addition, the center has a 10kN Shimadzu electro-mechanical machine for testing of smaller specimens. The CTMFM also has four multicore work-stations for conducting parallel computations. Computational models for investigating material deformation and failure are developed utilizing both commercial codes and In-house FE codes (based on low and high order methods).

Research

- Ductile fracture modelling

- Powder compaction

- Thermo-mechanical bonding

- Small punch test modelling

- Composite material failure

- Micro-mechanics of AMCs

- Natural Fiber Composites

- Oocyte mechanics

- Skin mechanics

Ductile fracture modelling

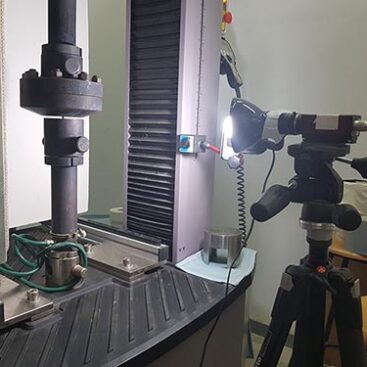

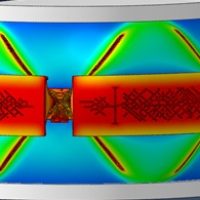

This goal of this study is to investigate damage initiation and evolution in ductile metals and metal matrix composites. A computational experimental methodology is used to identify the parameters that govern failure initiation and propagation. Based on the Continuum Damage Mechanics (CDM) approach, damage initiation is governed by the local history of triaxiality and plastic strain. Damage evolution is governed by local energy dissipation.

Powder compaction

This goal of this study is to investigate the pressure-density relationship in compaction of metallic/ceramic powders. Both continuum level models and micromechanical Relative Volume Element (RVE) representations are utilized. The continuum constitutive model parameters are identified by comparison to compaction experiments and local density measurements. The micro-mechanical models are used to determine how the different microstructural aspects of the powder particles such as size, shape, distribution and contact interactions influence the local porosity.

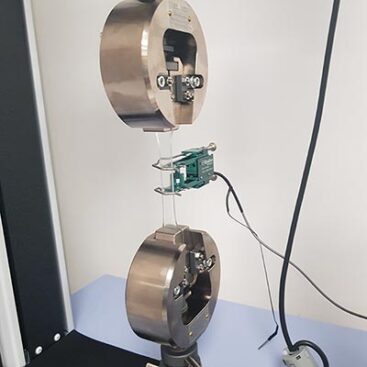

Bonding of Metallic layers by metal forming

This goal of this study is to investigate how the thermo-mechanical conditions of the forming process influence the overall mechanical strength of the bond. Hot roll bonding and compression experiments are utilized to generate the interface bond. Tensile and bending experiments are used to break the bonds. Thermo-mechanical computational models are utilized to compute the thermo-mechanical fields which develop at the interface during the forming process. Modeling of the bond strength is conducted using the cohesive zone (CZ) approach.

Small punch test modelling

Computational models are used to study the Small Punch Test (SPT) method applied to metallic and composite films. The mechanical fields which develop during the loading process and the resulting fracture modes are examined. The influence of the experimental setup parameters on the determination of the yield stress, ultimate stress and elongation to failure is investigated. The computational models provide insight on the proper method for analyzing the SPT experiments and on the limitations of the method.

Composite material failure

The effective mechanical response and failure of Aluminum Matrix Composites (AMC’s) is studied using finite element analysis and implementing a Continuum Damage Mechanics (CDM) approach. The model are validated against experiments.

Micro-mechanics of AMCs

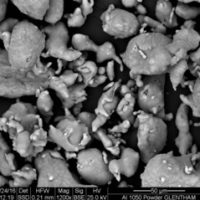

The effective mechanical response of Aluminum Matrix Composites (AMCs) manufactured using powder metallurgy is studied. Representative Area Elements (RAE) of the real composite microstructure are generated from Scanning Electron Microscopy (SEM) images. The RAE models are used to conduct micromechanical computations which take into consideration the mechanical interactions between the different constituents and the particle morphology. The influence of particle-matrix bonding conditions is also investigated.

Natural Fiber Composites

The effective elastic response of composites composed of natural fibers (Sisal) embedded in an epoxy matrix is investigated. Unidirectional lamia containing different volume fractions of Sisal fibers are manufactured and testes up to failure in various loading directions. Analytical and computational models are used to determine the effective elastic properties. By utilizing Hashin’s failure criteria the different failure modes are examined.

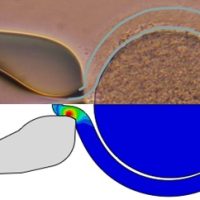

Oocyte mechanics

Computational modeling is utilized to determine the mechanical parameters that govern deformation of the human female reproductive cell (Oocyte). Images from clinical ICSI protocols are used to construct patient specific oocyte models and determine the loading conditions. By a process of iterative computations, the material properties of Zona Pellucida (ZP – the outer membrane of the oocyte) are identified. It is demonstrated that by using the identified ZP mechanical properties it is possible to improve the potential for a successful implantation which will lead to pregnancy.

Skin mechanics

This goal of this study is to investigate how different genetic treatment protocols for tissue regeneration influence the mechanical response of skin tissue. The skin of different genetically treated mice are harvested and tests under uniaxial extension. Computational models of the experiments are utilized to characterize the parameters for a hyper-elastic constitutive model of the skin tissue. The relation of the model parameters to the different treatment protocols are examined.

Ductile fracture modelling

This goal of this study is to investigate damage initiation and evolution in ductile metals and metal matrix composites. A computational experimental methodology is used to identify the parameters that govern failure initiation and propagation. Based on the Continuum Damage Mechanics (CDM) approach, damage initiation is governed by the local history of triaxiality and plastic strain. Damage evolution is governed by local energy dissipation.

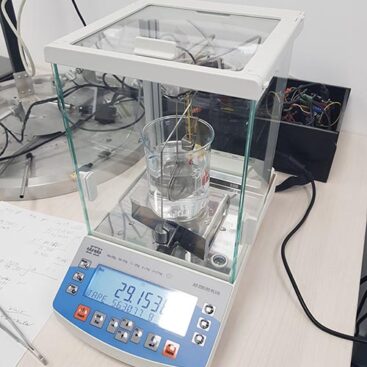

Powder compaction

This goal of this study is to investigate the pressure-density relationship in compaction of metallic/ceramic powders. Both continuum level models and micromechanical Relative Volume Element (RVE) representations are utilized. The continuum constitutive model parameters are identified by comparison to compaction experiments and local density measurements. The micro-mechanical models are used to determine how the different microstructural aspects of the powder particles such as size, shape, distribution and contact interactions influence the local porosity.

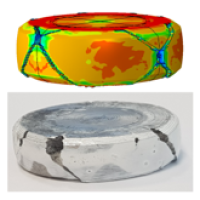

Bonding of Metallic layers by metal forming

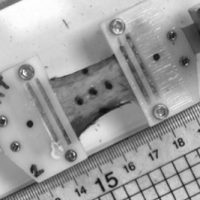

This goal of this study is to investigate how the thermo-mechanical conditions of the forming process influence the overall mechanical strength of the bond. Hot roll bonding and compression experiments are utilized to generate the interface bond. Tensile and bending experiments are used to break the bonds. Thermo-mechanical computational models are utilized to compute the thermo-mechanical fields which develop at the interface during the forming process. Modeling of the bond strength is conducted using the cohesive zone (CZ) approach.

Small punch test modelling

Computational models are used to study the Small Punch Test (SPT) method applied to metallic and composite films. The mechanical fields which develop during the loading process and the resulting fracture modes are examined. The influence of the experimental setup parameters on the determination of the yield stress, ultimate stress and elongation to failure is investigated. The computational models provide insight on the proper method for analyzing the SPT experiments and on the limitations of the method.

Micro-mechanics of AMCs

The effective mechanical response of Aluminum Matrix Composites (AMCs) manufactured using powder metallurgy is studied. Representative Area Elements (RAE) of the real composite microstructure are generated from Scanning Electron Microscopy (SEM) images. The RAE models are used to conduct micromechanical computations which take into consideration the mechanical interactions between the different constituents and the particle morphology. The influence of particle-matrix bonding conditions is also investigated.

Oocyte mechanics

Computational modeling is utilized to determine the mechanical parameters that govern deformation of the human female reproductive cell (Oocyte). Images from clinical ICSI protocols are used to construct patient specific oocyte models and determine the loading conditions. By a process of iterative computations, the material properties of Zona Pellucida (ZP – the outer membrane of the oocyte) are identified. It is demonstrated that by using the identified ZP mechanical properties it is possible to improve the potential for a successful implantation which will lead to pregnancy.

Skin mechanics

This goal of this study is to investigate how different genetic treatment protocols for tissue regeneration influence the mechanical response of skin tissue. The skin of different genetically treated mice are harvested and tests under uniaxial extension. Computational models of the experiments are utilized to characterize the parameters for a hyper-elastic constitutive model of the skin tissue. The relation of the model parameters to the different treatment protocols are examined.

The effective elastic response of composites composed of natural fibers (Sisal) embedded in an epoxy matrix is investigated. Unidirectional lamia containing different volume fractions of Sisal fibers are manufactured and testes up to failure in various loading directions. Analytical and computational models are used to determine the effective elastic properties. By utilizing Hashin’s failure criteria the different failure modes are examined.

- E. Priel, B. Mittelman, L. Efraim, T. Priel, I. Szaingurten-Solodkin, I. Har-Vardi, “Hyperelastic models for the human Zona Pellucida and their implications on shear modulus estimation in the clinical practice, Accepted for publication in Scientific reports, December 2024.

- B. Mittelman, N. Rom, Z. Yosibash, E. Priel, “Predicting failure initiation at V-notch tips in an AISI 4340 alloy by a continuum damage model”, Engineering fracture mechanics, Vol302, 110067, 2024.

- N. Rom, J. Bortman, E. Priel, “Predicting ductile failure of aluminum components under general loading conditions: Computational implementation, model verification and experimental validation”, International Journal of Solids and Structures, Vol275, 112295, 2023.

- M. Ben-Haroush, B. Mittelman, R. Shneck, E. Priel, “The influence of time, atmosphere and surface roughness on the interface strength and microstructure of AA6061-AA1050 diffusion bonded components”, Materials, Vol 16, 769, 2022.

- E. Priel, B. Mittleman, N. Trabelsi, N. Lulu-Biton, S. Haroush, S. Kalabukhov, S. Hayun, N.U. Navi, Small Punch Testing of Al-TiB2 composites fabricated by Spark Plasma Sintering: A computational and experimental study, Journal of Composite Materials, 2022, https://doi.org/10.1177/00219983221127007

- O. Sinitsky, N. Trabelsi, E. Priel, “The mechanical response of epoxy-sisal composites considering fiber anisotropy: A computational experimental study”, Fibers, 10:43, 2022.

- A. Farkash, B. Mittelman, S. Hayun, E. Priel, “Aluminum matrix composites with weak particle matrix interfaces: Effective elastic properties investigated using micromechanical modeling”, Materials, 14:6083, 2021.

- B. Mittelman, M. Ben Haroush, I. Aloush, L. Mordechay, E. Priel, “Bonding of Al6061 by hot compression forming: A computational and experimental study of interface conditions at bonded surfaces”, Materials, 14:3589, 2021.

- E. Priel, T. Priel, I. Szaingurten-Solodkin, T. Wainstock, Y. Perets, A. Zeadna, A. Harlev, E. Lunenfeld, E. Levitas, I. Har-Vardi,”Zona pellucida shear modulus, a possible novel non-invasive method to assist in embryo selection during in-vitro fertilization treatment, Scientific reports, Vol 10, 2020.

- E. Priel, N.U. Navi, B. Mittleman, N. Trabelsi, M. Levi, S. Kalabukhov, S. Hayun, “Cold forming of Al-TiB2 composites fabricated by SPS: A computational experimental study”, Materials, Vol 13, 2020.

- M. Aizenshtein, E. Priel, S. Hayun, “Effect of pre-deformation and B2 morphology on the mechanical properties of Al0.5CoCrFeNi HEA”, Materials Science and Engineering A, Vol 788, 2020.

CURRICULUM VITAE

Name: Elad Priel

Date & place of birth: December 18, 1977, Haifa, Israel. Citizenship: Israeli

Marital status: Married +3.

Affiliation: NRCN-Department of Materials Science and SCE – Mechanical Engineering Department, Beer Sheva, P.O.B. 950, 84100.

Tel: +972-8-6475699.

E-mail: eladp@sce.ac.il.

Residence address: Mezadot Yehoda (Bait-Yatir) Military service: 1996-2000 (Medic)

- Academic education

2007-2011 Ph.D. in Mechanical Engineering. Ben Gurion University of the Negev, Israel. Dissertation title: The coupled passive active response of the human artery wall investigated by p-FEM’s. Adviser: Prof. Yosibash, Z.

2005-2007 M.Sc. in Mechanical Engineering. Ben-Gurion University of the Negev, Israel. Dissertation title: Mixed mode failure criteria for V-notched brittle elastic structures. Adviser: Prof. Yosibash, Z.

2001-2005 B.Sc. in Mechanical Engineering (Graduated with excellence). Ben-Gurion University of the Negev, Israel.

- Employment

2012-Present Senior researcher, R&D Division, Materials Science department, NRCN. 2019-Present Senior Lecturer. Mechanical Engineering department, SCE – Sami Shamoon

College of Engineering, Israel.

2013-2019 Lecturer. Mechanical Engineering department, SCE – Sami Shamoon College of Engineering, Israel.

- Academic research and development activities

- Previous research and development activities

2007-2011 Investigation of the coupled passive active mechanical response of the human artery wall using high order finite element methods.

2007-2011 Development of a novel 3D p-version finite element program for solving non-linear boundary value problems in anisotropic hyper-elastic structures.

2005-2007 Development of failure initiation criteria for mixed mode loading of V- notched brittle structures

- Present research and development activities

Since 2013 Computational and experimental metal forming

Since 2013 A computational and experimental studies of the Small Punch Test method applied to thin metallic foils

Since 2013 A computational and experimental study of human oocyte Zona pellucida mechanics – In collaboration with Soroka Medical Center – IVF Unit.

Since 2013 A computational and experimental study of human skin mechanics using high order p-version finite element methods.

Since 2019 Multiscale modelling of AMCs from powder compaction to effective properties.

- Grants and awards

- Grants

2022-2026 E. Priel, N. Trabelsi, Y. Gelbstein (NRCN, SCE and BGU), Predicting the influence of microstructural parameters on the effective thermal and mechanical properties of metal matrix composites, Pazy Foundation Grant (IAEC), 532,800$ (133,200$ for each year).

2022-2023 Shanek R. and Priel E. (BGU and SCE), Reactive structural materials, IMD, MAFAT, 72700$ (31,250$ SCE part).

2021-2024 Priel, E and Har-Vardi, I. (SCE – Sami Shamoon College of Engineering & BGU), The mechanical response of the human Zona Pellucida and its influence on embryo implantation potential during in-vitro fertilization treatment (Israel Science Foundation – ISF), 140,000$.

2020-2021 Priel, E and Trabelsi, N. (SCE – Sami Shamoon College of Engineering) Investigting powder compaction and aluminum bonding. Industry Grant from the Israli Atomic Energy Commision (IAEC), 60,000$.

2017-2020 Priel, E and Trabelsi, N. (SCE – Sami Shamoon College of Engineering) Investigting the mechanical properties of Aluminum Metrix Composites (AMC’s). Industry Grant from the Israli Atomic Energy Commision (IAEC), 282,000$. (for 3 years)

2017 -2018 Priel, E and Trabelsi, N. (SCE – Sami Shamoon College of Engineering), A computational study of Equal Channal Angular Extrusion of Molibdinum, Industry Grant from Refael Advanced Defence Systems Ltd., 8500$.

2016-2017 Priel, E (SCE- Sami Shamoon College of Engineering), A computational and experimental study of human skin mechanics, Grant from the SCE research authority 8500$.

2013-2016 Priel, E (SCE- Sami Shamoon College of Engineering), A computational study of the mechanics of the human oocyte zona pellucida, Grant from the SCE research authority 25000$.